Guidelines

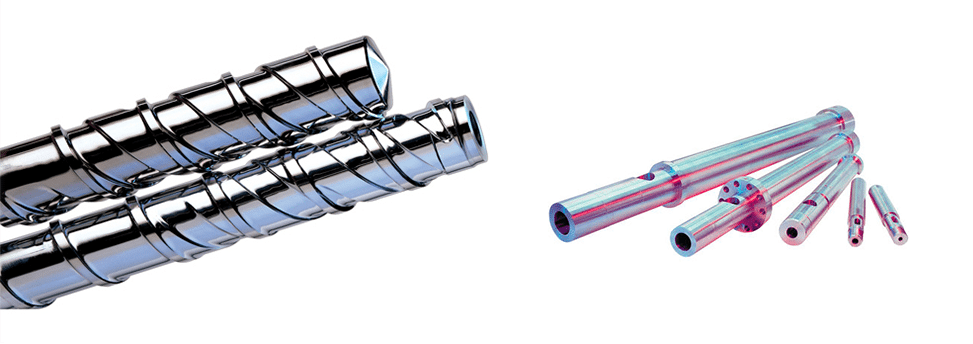

These are the Recommended Maximum Wear Clearances between screw and barrel for best output performance

| Screw Size | New Part Clearance | Worn Clearance | Max Wear Clearance |

|---|---|---|---|

| 1″ | .003-.004″ | .018″ | .020″ |

| 1-1/2″ | .005-.008″ | .020″ | .025″ |

| 2-1/2" | .007-.010" | .021" | .030" |

| 3-1/2″ | .010-.012″ | .030" | .036″ |

| 4-1/2″ | .010-.013″ | .030" | .039″ |

| 6″ | .013-.016″ | .039" | .048″ |

| 8″ | .016-.019″ | .048" | .057" |

| 10″ | .018-.021″ | .054" | .063″ |

| 12″ | .020-.025" | .060" | .075″ |

Screws should be rebuilt when dimensions reach the worn clearance measurements as product quality is being affected. When dimensions reach the maximum clearance, performance (output and product quality) suffers greatly.

Here is a typical payback example using a 4.5" dia x 24:1 barrier screw processing polyolefin:

Nominal Rate – 1,500 lbs/hr

Melt Temperature – 420 to 430° F.

Output Stability – +/- 5%

Effects of diametrical wear factor of .025-.030 may result in a 60 lb/hr output reduction due to wear

Nominal Rate – 1,440 lbs/hr

Melt Temperature – 430 to 450° F.

Output Stability – +/- 10%

Penalty Cost: 60 lbs/hour x 0.65 = $ 65.00 /hour x 24 hours = $936.00 per day

A typical screw rebuild for a 4.5" Dia X 24:1 Barrier Screw with Colmonoy 56 hard surfacing costs $3,642. with a 2 week delivery.

Your Return on Investment Payback is 3.89 days

If you are planning on rebuilding your screws, take advantage of Xaloy's screw rebuilding cell that features fast turnarounds (7– 14 days) on your screws. Streamlined using Lean manufacturing principals, we can receive incoming screws for inspection, estimate costs, quote and release to the shop with your approval within 24 hours of receiving the parts.